Organic nitrogen molybdenum fullerene

lubricant additive SDT3003

Molybdenum fullerene organic nitrogen in the

normal condition of lubricant lubricated parts, on the friction surface will

form a physical and chemical adsorption film, this film with anti-friction,

anti-wear effect. When in the high speed, high temperature, high pressure and

other harsh conditions, on the friction pair surface will form the molybdenum

element penetration layer and the fullerene C60 eutectic rolling lubrication

layer. Since fullerenes itself globular shape and the characteristics of high

temperature resistant, toughness, super lubrication; so convert the sliding

friction into rolling friction.This greatly reducing wear between the

components, achiving best anti-wear, anti-friction, wear scar repair effect.

For other additives,these effects are hard to achive.

This new unique lubrication structure,

pioneered the chemical adsorption film, special element permeable formation,

eutectic rolling lubrication layer multiple lubrication mode. It exponentially

increase the extreme pressure antiwear performance, greatly reduce the friction

coefficient, obviously inhibit oil temperature rise, also has long-lasting

lubrication effect and outstanding high temperature anti-oxidation function.

Key Performance Benefits

Super extreme pressure antiwear performance

Outstanding high temperature anti-oxidation

Long-lasting lubrication performance

Good

oil solubility

Good

ability to inhibit oil temperature rise

Description

Organic nitrogen molybdenum fullerene lubricant

additive is a highly effective and environmentally friendly lubricant additive.

It is developed by State Key Laboratory of tribology,

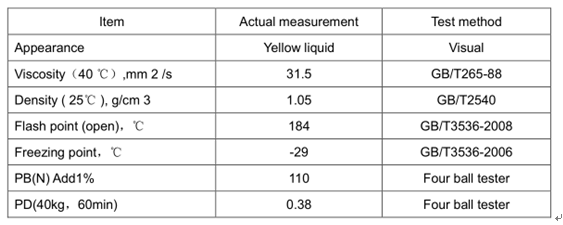

Typical Characteristic

Recommended Dosage: 1%—3.5%

Packing and storage

Packing:20KG/Drum or 200KG/Drum.

Please refer to SH/T0164 standard when

stored, loaded and unloaded, oil blending. Keep the temperature not higher than

75°C. For long-term storage, the suggested temperature is lower than 45°C.

Typical test data

The lowest friction coefficient can reach

0.0225, and the grinding spot diameter is 0.31mm.

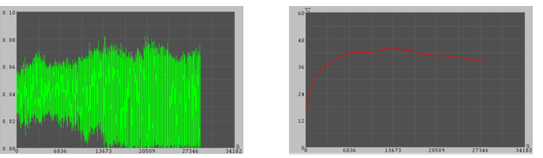

Above picture is the friction coefficient and temperature change detection figure:40KG,9 hours; it shows that,with time changes, the average friction coefficient of fullerene lubricant is almost no change. And the temperature gradually decreased with the time changes. As time increases, the eutectic rolling lubrication occurs, the formation of unique permeable layer to protect the engine from wear, with good lubrication, so the temperature

drops, from the highest 44.5 ℃ to 38.5 ℃. And it will also drop to a certain temperature with the

increase of time.